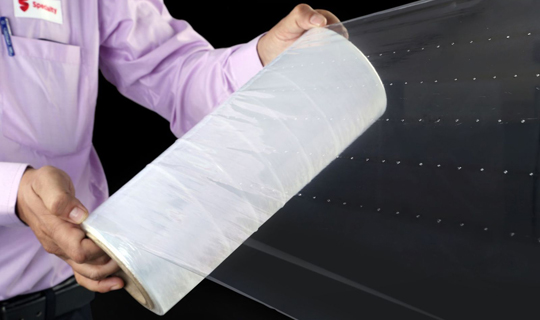

Mushroom Packaging film has micro holes that allow air permeation to maintain the rate of respiration. Micro-perforation involves making holes in the film ranging from a diameter of 1 mm to 2 mm either by cold or hot needles, or laser processes.

Micro-perforation is essential for packed mushrooms, since the film ensures that products can breathe and the air inside the package can be circulated. It helps in sustaining quality, freshness, and integrity of the contents, enhancing greater shelf life. Most common is the 5-line micro-perforation — however, we can produce different patterns of micro-perforation as required by the customer or the application.