For USA, Canada: forvara.foodservice@specialty-films.com

For EU, UK and Rest of the world: wrapit.export@specialty-films.com

| Width (inch) | Length (ft) | Thickness (ga) | Cutter Type |

|---|---|---|---|

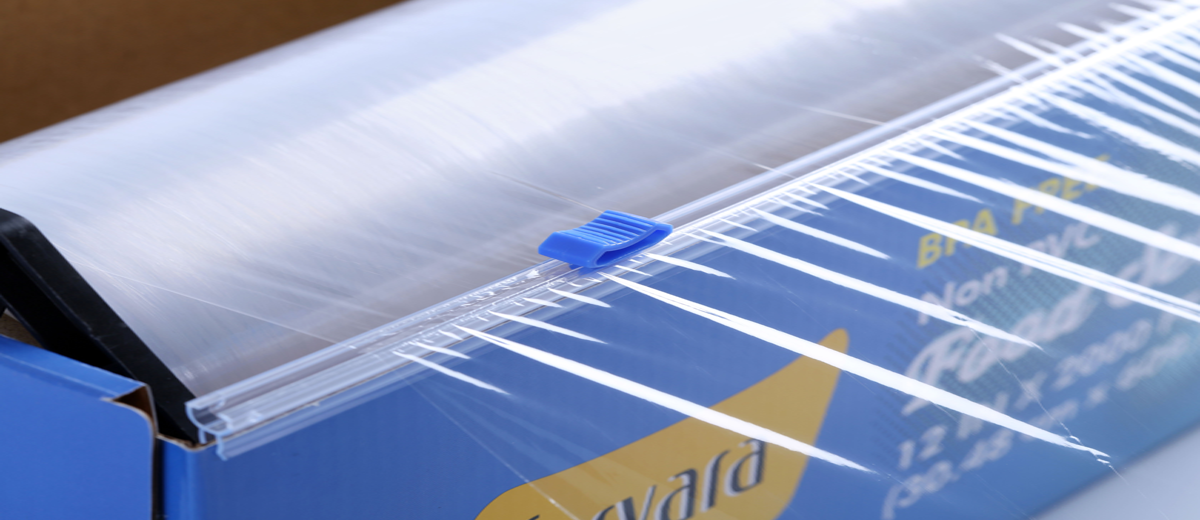

12 | 2000 | 36 | Sliding Cutter |

18 | 2000 | 36 | Sliding Cutter |

24 | 2000 | 36 | Sliding Cutter |

| ATTRIBUTE | SPECIFICATIONS |

|---|---|

Width | 6 – 24 in |

Thickness | 32 – 60 Gauge |

Length | 500 – 3000 ft. |

Core Size | 2/2.28 in |

Primary Packaging | Film roll in cutter box.Plastic or self-core holder for smooth dispensing. |

Cutter Variant | Plastic serrated.Push/stick on slide cutter. |

Secondary Packaging | Master Carton, SRP/Display cases, Shrink wrap |

For USA, Canada: forvara.foodservice@specialty-films.com

For EU, UK and Rest of the world: wrapit.export@specialty-films.com

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |