Foodservice Film

Forvara® Foodservice

Film

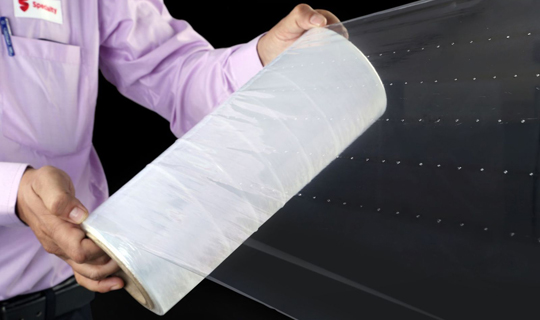

Forvara® Foodservice Films are high-quality professional food wrapping films with exceptional strength, tackiness and see-through clarity. With environment and health concerns at the core of product development, our films are 100 percent recyclable and free of harmful chemicals.

Forvara® Foodservice Films are manufactured through a specially engineered combination of select food-grade polymers and process innovation to produce material free from taste and odour. Specialty Polyfilms has been manufacturing plastic/cling wrap for more than a decade as a private label manufacturer for top retailers worldwide. Our experience of working with global organizations along with continuous research and development has resulted in creating world class PVC replacement, PE-based foodservice films.

Foodservice Films are specially developed for professional use in commercial kitchens, restaurants and supermarkets as an overwrap to cover food trays. In the household segment, most plastic or cling wraps sold by national brands are made of polyethylene (PE). However, the HoReCa industry still uses PVC film for food covering and meat wrapping. Specialty Polyfilms have succeeded in developing a PE-based alternative that is functionally superior than conventional PVC film.

Forvara® Foodservice Film caters to the HoReCa segment through foodservice distributors and food management services companies. It is distributed through our wholly-owned subsidiary Specialty America Inc. in the North American markets. We have warehouses on the East and West coasts to ensure efficient deliveries to customers across the US market.

Our new game-changing PVC like (PVCL) Polyethylene film

PVC Like (PVCL) polyethylene films are developed to emulate the key physical attributes of PVC films, like tackiness, softness and transparency. PVCL films have even proved better than the PVC films in many of these attributes.

PVCL polyethylene films have been recognized and placed among the most innovative products in some of the biggest trade shows of the industry, like IFFA–Frankfurt, Germany, 2019 and PLMA–Amsterdam, Netherlands, 2019, to counter the ecological strain caused by the much-debated PVC films.

It is now time-tested that the user would find no difference in usage of our PVCL film as compared to PVC ones, from the functional point of view.

To know more about this product from our Sales team, email us at:

For USA, Canada: forvara.foodservice@specialty-films.com

For EU, UK and Rest of the world: wrapit.export@specialty-films.com

Film

Characteristics

Hassle-free Experience

Easy dispensing, smooth cutting and optimum cling allows wrapping of food without the hassle of film entanglement around containers.

High Stretchability

High stretchability and good memory helps to stretch, wrap and seal food trays.

Crystal Clear Transparency

High optical transparency provided for see-through packaging of food items.

Odourless

No obnoxious smell compared to PVC films.

BPA Free

Bisphenol A (BPA) free and does not contain any plasticizers such as phthalates, stabilizers, chlorine content or any chemicals that are harmful to human health.

Microwave safe

The film does not release toxic substances into wrapped food when heated.

Tear and Puncture Resistant

Allows accommodation of odd-sized sealing without tearing.

Excellent Breathability

Helps to keep food fresh to enjoy its original taste.

Soft and Wrinkle-Free Film

Soft and smooth surface texture.

100% recyclable & eco-friendly

Polyethylene is easily recycled without releasing any harmful substances in to the environment.

Product

Variants

Perfa – Perforated film

These films have perforations at a specified equal distance, eliminating the need for a cutter. They offer the following advantages:

- Perforated sheets are easy to cut and reduce waste

- 40% productivity improvement for batch packing

- Eliminates cutter, leading to safe handling

- Perforation intervals can be customized as per the customer requirements

Biodegradable film

Specialty Polyfilms is committed to developing sustainable products. After years of research and development, we have successfully introduced biodegradable foodservice films. With the world moving on to sustainable packaging, our films are a preferred alternative to conventional PVC foodservice films.

With the biodegradable product, we aim to bring a positive effect on the environment and reduce the use of non-biodegradable single-use plastic.

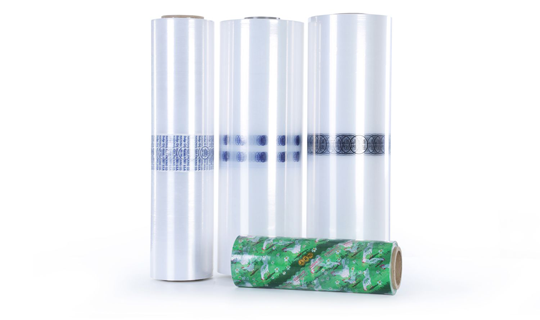

Private Label

Manufacturer

We have been a member of the Private Label Manufacturers Association (PLMA) for over 15 years and are regular exhibitors at PLMA shows across Europe and the US.

Our production and packaging capabilities enable us to offer customized size, cling, thickness and packaging for your brands. With more than a decade of experience working as private label manufacturers, we can provide customised film and packaging as per consumer needs.

Product

Specification

Standard SKU’s

| Width (inch) | Length (ft) | Thickness (ga) | Cutter Type |

|---|---|---|---|

12 | 2000 | 36 | Sliding Cutter |

18 | 2000 | 36 | Sliding Cutter |

24 | 2000 | 36 | Sliding Cutter |

Specifications

for Private Label

| ATTRIBUTE | SPECIFICATIONS |

|---|---|

Width | 6 – 24 in |

Thickness | 32 – 60 Gauge |

Length | 500 – 3000 ft. |

Core Size | 2/2.28 in |

Primary Packaging | Film roll in cutter box.Plastic or self-core holder for smooth dispensing. |

Cutter Variant | Plastic serrated.Push/stick on slide cutter. |

Secondary Packaging | Master Carton, SRP/Display cases, Shrink wrap |

Customized sizes, properties, packaging and colors are also available.

Film and Package

Customization

Our engineered combination of raw materials, process innovation and a highly skilled production team enables us to custom-make cling wraps as per our consumers’ requirements — be it in strength, flexibility, elongation, thickness or cling.

Film Color:

Transparent natural color or tinted colors.

Box Design:

Customization of box design with multicolor printing, packed in FSC certified cartons.

Value-added Features:

Roll holder, easy-to-find film from the pack, V-shaped curling of film reminder label or paper label.

Combo/Refill Pack:

Bare refill roll can be used when a consumer runs out of plastic wrap.

Combo Bundle Pack — two or more plastic wrap boxes are wrapped together to make a combo pack.

Secondary Packaging:

Shelf ready/display packs, master cartons, shrink wrap.

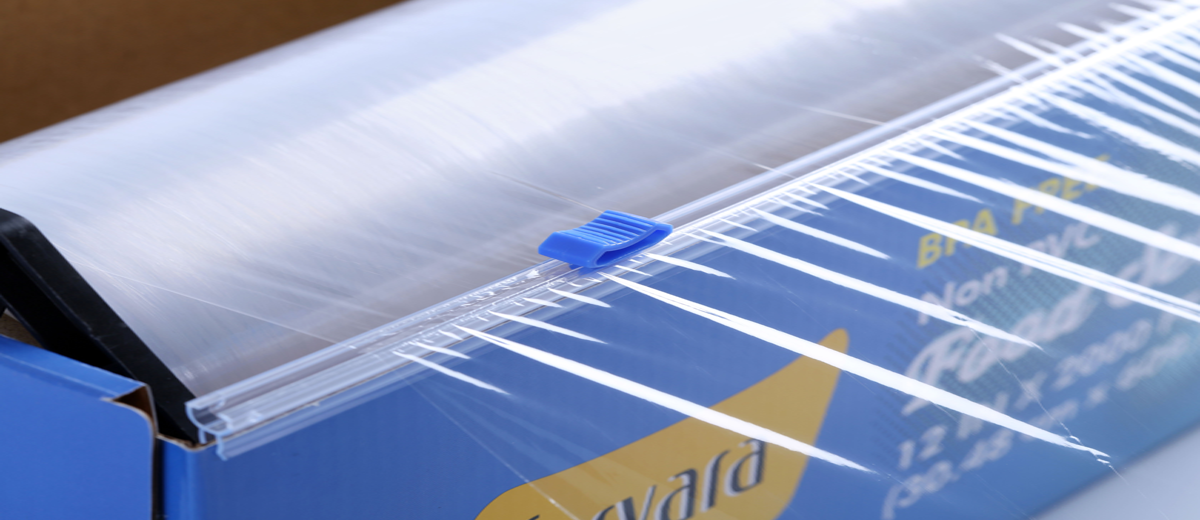

Cutter Blade Variants:

Plastic (PET), plastic serrated or slide cutter (stick-on and push-on).

State-of-the-art packaging with slide cutter variant enhances the user experience with smooth cutting of film.

The blade on the cutter is not exposed, eliminating any accidental cuts or injuries. It cuts the film easily and thereby, reduces wastage.

Why Polyethylene?

Forvara® Foodservice Film is PVC Like (PVCL) polyethylene film. Polyethylene (PE), the base material used in manufacturing Forvara® & Wrapit® Films, is a simple structure polymer that has the least environmental impact. It is easily recyclable and when annihilated, it burns to hydrogen and carbon without any polluting content.

Polyethylene Films are an ideal replacement for conventional films that contain toxic plasticizers (such as phthalates), hazardous heavy metals (such as lead and mercury), fungicides and other toxic substances that are harmful for human health.

Our new game-changing PVC like (PVCL) Polyethylene film

PVC Like (PVCL) polyethylene films are developed to emulate the key physical attributes of PVC films, like tackiness, softness and transparency. PVCL films have even proved better than the PVC films in many of these attributes.

PVCL polyethylene films have been recognized and placed among the most innovative products in some of the biggest trade shows of the industry, like IFFA–Frankfurt, Germany, 2019 and PLMA–Amsterdam, Netherlands, 2019, to counter the ecological strain caused by the much-debated PVC films.

It is now time-tested that the user would find no difference in usage of our PVCL film as compared to PVC ones, from the functional point of view.

Advantage

Specialty

Research and Innovation:

We have a center of excellence to research and test food wrap films for specialized consumer needs of retailers and brand owners.

Product Differentiation:

100 percent recyclable PE films do not leave any traces on food, nor do they have an obnoxious smell. This gets the user to experience the original taste of the wrapped food.

Process Expertise:

Our expertise in process engineering enables us to achieve consistency, traceability and reliability in every product delivery.

Economies of Scale:

We leverage economies of scale with high throughput, modern and efficient production lines, global polymer procurement and integrated supply-chain logistics.

Regulatory

Compliance

BRCGS Packaging Material certified Company.

Does not contain Bisphenol A (BPA), which is unsafe for the food.

Meets latest food contact regulations as per FDA – 21 CFR 177.1520

Meets the latest food contact regulations as per EU directive no. 10/2011 (Ref. 2002/72/EEC)

Does not contain any chemicals from the California Prop. 65 list of harmful chemicals.

Approved raw-material, no cross-contamination with non-kosher products

Specialty

America

Specialty Polyfilms incorporated a subsidiary — Specialty America Inc., New Jersey — to facilitate localised purchases in the US. Specialty America provides a hassle-free alternative to importing products to the US. We have warehouse facilities located on the East and West coasts for stocking and distribution.

To know more about this product from our Sales team, email us at:

For USA, Canada: forvara.foodservice@specialty-films.com

For EU, UK and Rest of the world: wrapit.export@specialty-films.com