Looking for Protective Packaging

In

Our Vision

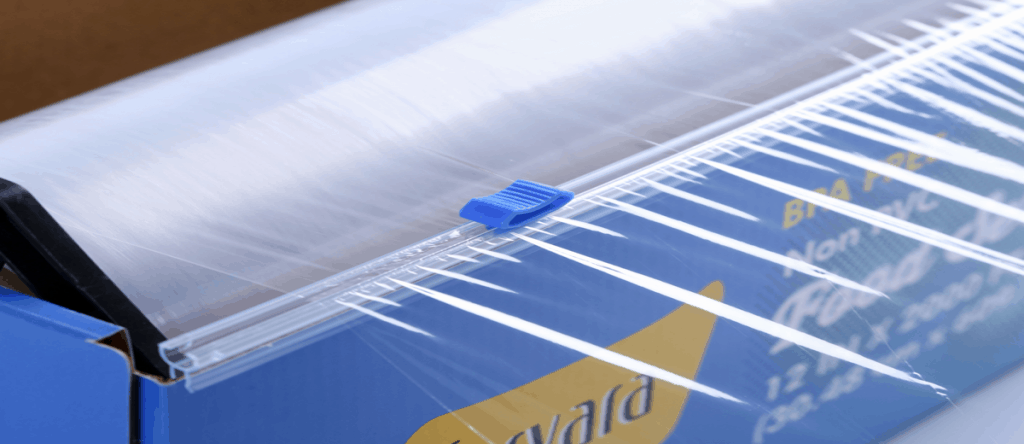

New Launch

Forvara® Plastic/Cling Wrap Film

Forvara® has added 300 sq.ft. variant in its product range, it is designed with a sliding cutter providing you with a hassle-free dispensing and cutting experience.

Upcoming Exhibitions

IPPE 2024

- Venue

- Georgia World Congress Center 285 Andrew Young International Blvd NW Atlanta, Georgia USA

- Duration

- 30th Jan- 1st Feb 2024

- Booth

- B45059

- Hall

- C HALL and BC HALL - Meat & Poultry Processing and Packaging

HRC 2024

- Venue

- ExCeL London, Royal Victoria Dock, 1 Western Gateway, London E16 1XL

- Duration

- 25 - 27, March 2024

- Booth

- H315

- Hall

- Foodservice Section

NRA Tradeshow 2024

- Venue

- McCormick Place, Chicago, IL, USA

- Duration

- 18 - 21 May, 2024

- Booth

- -

- Hall

- -

Global Certification

What our customers say

We developed a great partnership with Specialty Polyfilms, and their commitment to meet our stringent requirements even at the unprecedented global crisis is commendable. It is such a great experience to work with Team Specialty with their revolutionary products and “One of the best products ever tested…..A game-changing product

Specialty has been one of our most reliable & competitive suppliers since long. They understand our requirements very well and there were times when they went beyond and out of the way to deliver their commitments. What else do you expect from a supplier? Looking forward to many more years of business with them.

INDIA

Specialty Polyfilms India Pvt. Ltd.

F-89 & 102, M.I.D.C. Area, Waluj, Aurangabad – 431136, Maharashtra, India

Phone:

+91 9764441667 / 68

+91 240 2554045 / 46

Email:

export@specialty-films.com

USA

Specialty America Inc.

8351 N High Street,

Suite #285, Orchard Knoll

Columbus, Ohio 43235, USA

Phone:

+1.516.2522438

Email:

forvara.americas@specialty-films.com